Generators are invaluable tools for providing backup power during outages or serving as the primary power source in remote areas. However, like any machinery, they can encounter issues that disrupt their functionality. Generator error codes are essential tools in diagnosing and resolving these problems.

For the casual mechanic or home DIY-er, understanding generator error codes can help you self-diagnose the issue and quickly repair your generator without paying big bucks for repairs or buying the wrong part. Let's explore what generator error codes are, why they are important, and how to interpret and address some standard generator error codes.

What Are Generator Error Codes?

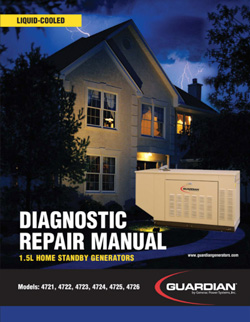

Generator error codes are alphanumeric or numeric identifiers generated by the generator's control panel or controller to indicate a specific issue or fault within the system. These codes help operators, technicians, and users pinpoint problems quickly and efficiently, allowing for a faster response and resolution. When a generator encounters an issue, it typically displays a code on the control panel or provides it in a diagnostic report.

Why Are Generator Error Codes Important?

- Generator error codes serve several crucial functions:

- Rapid diagnosis

- Prevent additional damage

- Safety

Error codes provide immediate insight into the nature of the problem, saving time and resources in troubleshooting. Instead of searching for the issue blindly, you can pinpoint it quickly. This speed helps you identify the problem, find the solution, and make the repair with the correct part, saving you time, money, and frustration. Need help finding matching parts? Use your Maintenance Part Finder!

Another essential feature of generator error codes is safety. Early identification of problems through error codes can prevent further damage to the generator or the connected electrical systems. This proactive approach minimizes repair costs and downtime.

Some Generac generator errors can indicate safety hazards. Identifying and addressing these issues promptly is essential to ensure the safety of personnel and property.

What Are the Most Common Generator Error Codes?

While generator error codes can vary depending on the make and model of your generator, there are some common Generac error codes and their meanings that you may encounter. Before troubleshooting any error code, ensure your safety by following all necessary safety protocols by turning off your generator and disconnecting it from the electrical load.

While generator error codes can vary depending on the make and model of your generator, there are some common Generac error codes and their meanings that you may encounter. Before troubleshooting any error code, ensure your safety by following all necessary safety protocols by turning off your generator and disconnecting it from the electrical load.

Most Common Generac Error Codes:

- Overheating

- Battery Power

- Overcrank

- Low Oil

- Overload

What is an Overcrank Code?

One of the most common generator error codes is 1100, or the Overcrank Code. The overcrank code means that although the engine is receiving a signal to start and the controller has verified that the engine is cranking, it's not able to do so. This code is typically related to maintenance or fuel.

How To Fix an Overcrank Code

First, check to make sure that the fuel supply is on. If you're using liquid petroleum gas, ensure the tank is not empty. Next, ensure the quality of the fuel by draining any old or contaminated fuel and replacing it. If you're still experiencing issues, inspect the fuel tank and filters for clogs or blockages and verify that the generator's battery is in good condition.

What is an Overspeed Code?

The overspeed codes usually display when the controller detects high RPM. This can be for a prolonged overspeed, typically when the engine runs over its set threshold for more than three seconds or instantaneous overspeed.

How to Fix an Overspeed Code

The 1200 overspeed eCode indicates a prolonged overspeed. It is usually caused by an issue with the mixer assembly or stepper motor, such as it coming unplugged, being jammed, or another issue that causes an increase in engine speed. Other alarms with an overspeed code can be caused by defective ignition coils. In these instances, we recommend contacting an authorized service dealer.

What is a Low Oil Pressure Code?

For Generac generators, low oil pressure typically results in a 1300-range code. This error code indicates that the generator's oil pressure is below the required level. Low oil pressure can lead to engine damage and should be addressed immediately. Check the oil level and inspect for any leaks in the oil system. You also may have a faulty low oil pressure switch or an internal problem with the engine's ability to establish and maintain oil pressure.

How to Fix Low Oil Pressure Code

If you are using your generator for extended periods, you may use more oil than you expect. Refilling your oil is the easiest fix if that is the cause of your low oil pressure code. However, replacing the low oil pressure switch or using an oil pressure test to check the engine are two other troubleshooting courses you may need to consider.

What is a High Temperature Code?

Overheating can damage the generator's components and reduce its lifespan. This error code suggests the generator runs too hot, possibly due to blocked cooling systems or insufficient ventilation. A high temperature error code is a safety feature for your generator that helps protect the systems and prevent catastrophic failure from occurring.

How to Fix a High Temperature Error Code

The first step in troubleshooting a high temperature error code on your generator is to ensure that the cooling system, including the radiator, coolant levels, and coolant circulation, is functioning correctly. Check for any obstructions or debris blocking airflow around the radiator or cooling fins, and then verify that the coolant reservoir or radiator contains an adequate amount of coolant.

For continued issues or if those solutions don't address the problem, check your oil levels, reduce the load on the engine, and ensure you don't have any coolant leaks.

What is Overload in a Generator?

An overload error code appears when the generator operates beyond its rated capacity. To put it into layperson's terms, imagine trying to carry multiple drinks. You only have two hands, and eventually, you're going to compromise the safety of each cup because you're trying to carry too many.

Your generator works in essentially the same way. When a generator is overloaded, it can lead to several problems and potentially damage the generator or connected equipment. Understanding overloads and how to manage them is crucial for the safe and efficient operation of a generator. Reducing the load on the generator or adding additional power sources may be necessary to prevent damage to the generator or a loss of power.

How to Fix a Generator with Overload

Every generator is designed with a specific electrical rating, which includes the maximum amount of power it can produce (expressed in kilowatts or kilovolt-amperes) and its voltage and frequency specifications. This rating is determined by the generator's engine capacity and the design of its electrical components.

To avoid overloading a generator, it is essential to manage the connected load effectively. This can be achieved by distributing the load across multiple generators if available or prioritizing essential equipment. If an overload is anticipated due to startup surges in equipment, consider using load management techniques, such as sequenced startup or load shedding.

What is Under Voltage?

Under voltage in a generator refers to a situation where the generator produces electrical output at a voltage level lower than the desired or rated voltage. This can be a critical issue, leading to various problems with electrical equipment and systems connected to the generator. There are several possible causes of under voltage for your generator:

- Overloading

- Engine speed

- Fuel supply

- Regulator issues

- Mechanical or electrical issues

- Generators that experience under voltage can be irreparably damaged, including:

- Equipment damage

- Stability issues

- Reduced efficiency

How to Fix a Generator with Under Voltage

Although under voltage may seem overwhelming at first, there are a few easy ways to troubleshoot this error code to find a solution. First, ensure that the total electrical load connected to the generator does not exceed its rated capacity. Distribute the load across multiple generators or prioritize essential equipment.

Second, if the generator has an adjustable engine speed, ensure it is set to the manufacturer's recommended specifications. Lastly, check the fuel supply and fuel quality, and test and replace any mechanical or electrical generator parts that may be triggering a code, such as the voltage regulator.

Why Do I Have a Low Battery Code on My Generator?

Not all generators run on petroleum or gasoline. Some generators run on battery power, and problems with your charge or connection can cause your generator display to throw error codes. Unlike other error codes, an issue with the battery typically displays a warning rather than an alarm.

If your battery voltage drops below 12.1 volts for over 60 seconds, your generator will display a Low Battery warning. This error could be due to a bad battery charger or a bad battery. Be sure to check the load test of your battery and the condition of the battery itself.

Another battery warning is Battery Problem. If your battery voltage exceeds 16 volts or your generator detects more than 600mA of charge current after the battery charges for 18 hours, your generator will display a Battery Problem error. If this occurs, remove and test your battery to determine if the problem is the controller or the battery itself.

Will My Generator Remind Me About Maintenance?

One of the best things about Generac generators is their ability to trigger maintenance reminders. There are two maintenance reminders programmed into standard Generac generators:

- Service Schedule A

- Service Schedule B

Service Schedule A is triggered two years from the date that your generator is first powered on or after 200 hours of run time, whichever comes first. This alert is a reminder to perform routine maintenance, such as replacing air filters, conducting battery testing, and checking and adjusting valves.

Service Schedule B is triggered four years from the first date of operation or after 400 hours of run time, whichever is first. If you didn't adjust your valves or make any replacements or updates to our filters, battery, or other mechanical or electrical parts during your Service Schedule A maintenance, you will almost certainly need to make these repairs now.

What to Do with Generator Error Codes

When your generator displays an error code, it may cause a bit of panic at first, especially if you're not familiar with your generator’s maintenance schedule or Generac diagnostic manual. However, there are a few quick and easy steps you can take to interpret and address the issue yourself:

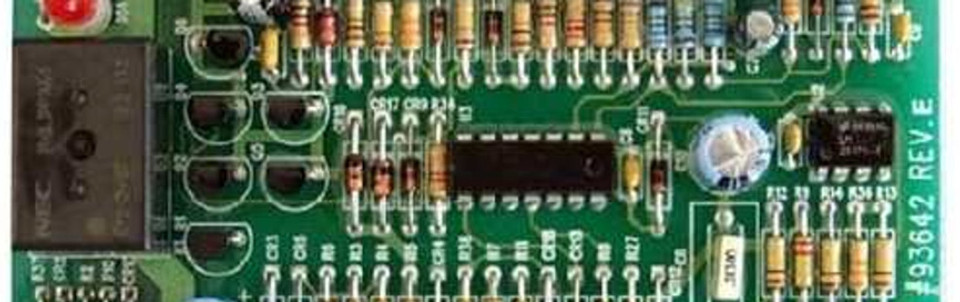

Consult the generator's manual: The generator's manual should have a section that lists error codes and their meanings. This is your first reference point for understanding the problem. You can also look up your error codes and troubleshoot issues with a diagnostic manual.

Check basic systems: Before calling for professional assistance or assuming that your generator is past its prime, perform basic checks, such as inspecting oil levels, checking fuel supply, and examining coolant levels. Many issues can be solved with a quick and easy fix.

Make a note of the error code: Take note of the error code displayed on the generator control board and any other information that you notice about the situation, such as abnormal environmental conditions, run times, and other factors. This information will be helpful if you need to discuss the problem with a technician.

Contact a Generac generator technician: If the issue remains unresolved or is beyond your capabilities, contact a certified generator technician to diagnose and repair the problem. They will have the necessary equipment and expertise to resolve complex issues and can help prevent costly mistakes if you're uncomfortable with making the repairs.

How To Reset an Alarm Or eCode On My Generac Generator

Although we believe that generator maintenance and repairs are things that you can do yourself, there are situations that call for consulting a professional. Many of the alarm codes your generator can display should only be reset by a Generac dealer or certified maintenance technician. Failure to perform the repairs or adjustments correctly can cause damage to your generator as well as any connected electronics or loads.

How To Clear a Maintenance Reminder

When your generator displays a maintenance reminder code and you have performed the needed adjustments, press the ENTER key to indicate that the repairs or inspections have occurred. You must press the ENTER key a second time to confirm your selection, or you can press ESCAPE to exit the prompt and keep the reminder active.

How to Clear an Alarm on Your Generac Generator

Once your generator has received the needed repairs or adjustments or the cause of the problem has been addressed, power down the unit by pressing the red OFF key. Next, press ENTER to confirm that the error has been repaired.

Then, place the unit back in AUTO or MANUAL mode with the corresponding key. MANUAL will power on the unit while AUTO will engage in automatic standby mode.

Please be aware that addressing some of the error codes mentioned in this tutorial requires specialized equipment and involves dangerously high electrical voltages that can be deadly.

Generator error codes are invaluable tools for diagnosing and resolving problems in generators. Understanding their meanings and taking prompt action can prevent further damage, minimize downtime, and ensure the generator operates reliably when needed. Regular maintenance and monitoring can help prevent many common issues that lead to these error codes, ensuring your backup power source is ready to perform when called upon.