When a storm ramps up or you need off-the-grid power, you feel better knowing that your generator is properly fueled and ready to go at a moment’s notice. Your generator’s fuel consumption can be a severe limiting factor in your machine’s electricity production, but with the right Generac fuel gauges and Generac fuel tanks, you can be confident that your generator’s engine will run with ease, giving you the power you need.

How Does a Generator Use Fuel?

Knowing how your generator works is the first step to staying on top of maintenance and damage surveillance. Your generator is a finely tuned machine, and understanding how all the parts — including the fuel system — work together will help you troubleshoot and know when you need Generac replacement parts.

Knowing how your generator works is the first step to staying on top of maintenance and damage surveillance. Your generator is a finely tuned machine, and understanding how all the parts — including the fuel system — work together will help you troubleshoot and know when you need Generac replacement parts.

Having a basic knowledge of your generator’s fuel system and how it impacts your equipment will help you with upkeep. A generator uses the fuel to engage the engine. The machine produces mechanical energy when the carburetor sends a fine, combustible fuel mist to the engine. The alternator then turns that mechanical energy into electricity through a process called electromagnetic induction, giving you the power you need.

Without the initial fuel intake, your generator won’t be able to carry out the rest of the electricity-producing process. This is why it is essential to keep up with the maintenance of your fuel system, including replacing Generac fuel gauges and Generac fuel tanks with OEM parts when necessary.

What Kind of Fuel is Used in Generators?

Before you head to the gas station or grab a propane tank, you should know exactly what kind of fuel your specific generator takes. There are many kinds of fuels used by generators, and each fuel type has its advantages and disadvantages. Most generators use one of four primary fuels:

- Gasoline

- Diesel

- Natural gas

- Propane

Some hybrid generator models allow you to switch between fuel types, but it is vital to check your user’s manual to ensure a fuel change will not negatively impact your equipment’s function. There may be specific grades of fuel that are better for your generator, so take the time to research precisely what you need before you put anything in your Generac fuel tank.

While not available for all generators, some units have dual fuel tanks. This gives you more fuel for longer runtime and the flexibility to choose between gas or propane, allowing you to lean into the advantages of each fuel type.

Gauges and Tanks in Your Generator’s Fuel System

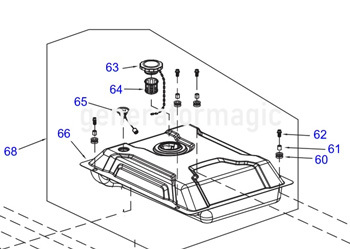

Without an in-depth knowledge of a generator’s inner workings, the average person knows that when they put fuel into the machine and then turn it on, they get electricity. Several components help get the fuel from intake to power production. The fuel system is a key component of your generator that includes:

Without an in-depth knowledge of a generator’s inner workings, the average person knows that when they put fuel into the machine and then turn it on, they get electricity. Several components help get the fuel from intake to power production. The fuel system is a key component of your generator that includes:

- Fuel gauges

- Fuel tank

- Fuel pump

- Fuel filter

- Fuel pressure regulator

- Fuel lines

- Fuel hoses

Having reliable Generac fuel tanks and accurate Generac fuel gauges is imperative to the success of your generator. Without these components, you have no way to know if your generator is fueled up and ready to go at a moment’s notice. Regular inspection and high-quality parts will keep your generator in good working condition.

Why Generac Fuel Tanks?

It is clear that your generator needs a reliable fuel system to run, and fuel tanks are an essential component of this system. The fuel storage of your equipment leads to efficient and safe generator operation, and it is worthwhile to consider dependable Generac fuel tanks when doing repairs. High-quality Generac replacement parts like fuel tanks will ensure your generator works well.

Depending on your generator, there are a variety of styles and features available for generator fuel tanks. For example, many generators have integrated tanks built into the machine, ranging from a few gallons to 20 gallons. Large generators that power major industrial areas or buildings have high generator fuel consumption and may use external tanks that hold a significant amount of fuel.

Purchasing the right Generac fuel tank is important to the overall function of your generator. When you have assessed your needs and considered all the options appropriate for your generator, you can make an informed decision regarding your fuel system’s Generac replacement parts.

Generac Fuel Tank Features to Consider

There are various factors to consider when choosing a generator fuel tank. Some of these are convenience related and others impact safety. Important points to consider when looking at Generac fuel tanks include:

- Capacity

- Fuel type

- Ventilation

Proper ventilation prevents pressure from building up and causing a disaster, and different fuel types require different materials for storage. Always check your generator’s manual before purchasing Generac replacement parts to ensure you get a fuel tank that’s the correct size and made of the right material.

Some fuel tanks are equipped with spill prevention safety measures to keep your immediate environment free from contaminants. This may include a double-walled fuel tank, or you may use a secondary containment system to prevent spills.

Portable vs. Standby Generac Fuel Tanks

Fuel storage in different kinds of generators requires different kinds of fuel tanks. Portable and standby generators have specific uses and, therefore, can accommodate differing tank styles.

Fuel storage in different kinds of generators requires different kinds of fuel tanks. Portable and standby generators have specific uses and, therefore, can accommodate differing tank styles.

The Generac fuel tanks of portable generators must not weigh down the generator too much, or the flexibility of being able to move the unit will be lost. Most portable generator tanks range from 1 to 8 gallons, making it easy to move the machine from one place to another. Because of their size, portable generator tanks must be refueled more often.

Standby generators are typically a permanent installation at a home or business, and can therefore accommodate much bigger Generac fuel tanks. One of these tanks may be able to hold anywhere from 50 to several hundred gallons of fuel at a time. This allows the generator to run at higher capacity and for longer periods of time before refueling is necessary.

What are Generator Fuel Tanks Made From?

Generac fuel tanks are made of various materials, each with its own benefits and drawbacks. Plastic tanks and metal tanks are two of the most popular types available, and which to choose largely depends on your specific generator.

Plastic Generac fuel tanks are lightweight and do not corrode like metal does. While durable enough for many situations, plastic is not as sturdy as metal tanks. A fuel tank made of plastic may also be susceptible to UV light damage, which is something to consider depending on where your generator is stored.

When it comes to metal tanks, steel and aluminum are both popular choices. Steel Generac fuel tanks are sturdy and capable of withstanding harsh environments and conditions, but they are more likely to rust and corrode over time if not maintained well. Aluminum, on the other hand, is naturally resistant to rust and corrosion. It is also lighter than steel but is still a durable option.

Generator Fuel Tank Maintenance

Regular fuel tank maintenance is essential to keep your generator running properly. Check your tank regularly for damage or leaks, make sure all the connections to fuel lines are secure, and monitor your generator’s fuel consumption for any irregularities. Keeping your tank free from debris and fuel contaminants with fuel filters will ensure the integrity of your Generac fuel tank.

Pay attention to your generator error codes to monitor any red flags that may pop up with your Generac fuel tank. Depending on the specific problem, maintenance or a repair may be necessary. If you need to look for a new tank, purchase genuine Generac replacement parts to ensure a good fit.

Why Generac Fuel Gauges?

You need precise and dependable Generac fuel gauges to keep track of your generator’s fuel levels. Having a generator gives you confidence that you will have power in the event of an emergency, but you cannot have that confidence if you don’t know for sure that your generator is fueled properly. By checking your Generac fuel gauge, you will know exactly how much fuel is in your generator and if you need to take action to be as prepared as possible.

You need precise and dependable Generac fuel gauges to keep track of your generator’s fuel levels. Having a generator gives you confidence that you will have power in the event of an emergency, but you cannot have that confidence if you don’t know for sure that your generator is fueled properly. By checking your Generac fuel gauge, you will know exactly how much fuel is in your generator and if you need to take action to be as prepared as possible.

With real-time information about your generator’s fuel levels, you avoid unexpected downtime in the power-producing process. Being caught off guard by low fuel when you are already desperate for power adds to the stress of the situation, so having Generac fuel gauges and knowing how to read them is paramount.

Why are Fuel Gauges Important?

Imagine driving down the road in your car without knowing when your gas might run out. Now, imagine you’re in that scenario, but it is dark and stormy outside, and none of your car’s lights are working. You never want to be in a situation where the generator you depend on for backup power is out of commission because of a lack of fuel, so reading your Generac fuel gauge is essential to your emergency preparedness.

Reading your generator’s diagnostic manual can show you which codes to look out for from the Generac fuel gauge in the machine. By understanding these codes and how to remedy them, you keep your generator adequately fueled and you can be prepared if the need for Generac replacement parts arises. Replacing a broken or faulty gauge with a genuine OEM Generac fuel gauge will ensure the equipment’s accuracy and your peace of mind.

How Fuel Gauges Work

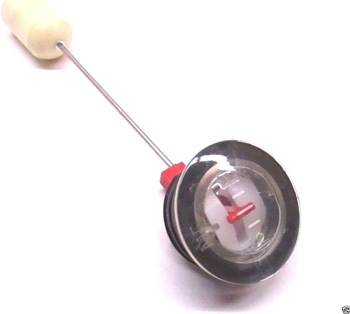

Managing your generator fuel level is easy when you know how to read and use your Generac fuel gauge. While there are multiple kinds of fuel gauges, the most common use a float-type mechanism to measure the fuel in your machine. With this kind of fuel gauge, a float sits on the surface of the fuel supply. It is attached to a resistance arm that moves as the fuel level changes, and the resistance can be translated to a signal that can be read on a control panel.

When considering how to get the best use out of your fuel gauge, consider using the data it provides for long-term fuel optimization. If you utilize one of the Generac fuel gauges that records data over time, you can analyze usage patterns to help your equipment stay efficient. You can also predict your maintenance needs by comparing your usage rates and data over time to anticipate generator reliability.

Generac Fuel Gauge Maintenance

Your generator’s overall maintenance is essential for the longevity and efficiency of your equipment, and regular inspection of your Generac fuel gauges should be a part of that scheduled upkeep. Before doing any maintenance on your generator, read the proper Generac diagnostic manual to ensure your repairs are done safely and correctly.

Your generator’s overall maintenance is essential for the longevity and efficiency of your equipment, and regular inspection of your Generac fuel gauges should be a part of that scheduled upkeep. Before doing any maintenance on your generator, read the proper Generac diagnostic manual to ensure your repairs are done safely and correctly.

One possible problem to check for in your Generac fuel gauges is faulty sensors, which can provide inaccurate readings. This can generally be avoided with regular upkeep and calibration. Fuel gauges can also be impacted by debris in the fuel or issues with the machine’s wiring, so replacing broken pieces with Generac replacement parts is critical for your generator’s overall performance.

Buying Generac Replacement Parts for Your Generator

When making necessary repairs to your generator, getting the best Generac replacement parts is essential. Ask essential questions when shopping to make sure you get the right Generac fuel gauges and tanks — along with other system elements, including the fuel pressure regulator, fuel line, and fuel hose — or you could wind up with leaks or poor system efficiency.

Ensure you use genuine OEM Generac replacement parts when making repairs to your generator. With OEM parts, you get elements that are made for the original production of the machine, meaning they will fit properly and work seamlessly with the rest of the system. Plus, with Generac replacement parts, you know you are getting quality backed by a 30-day warranty.

Fueling is an essential process that keeps your generator working. Your machine’s fuel system — including the Generac fuel tanks and Generac fuel gauges — must be of high quality so you can have confidence that you will be able to access power whenever needed. With the right fuel system in place and proper maintenance scheduled, your power production will go off without a hitch.